PROJECTS

PDF Laser Hair Removal Speed Sensor

System Overview

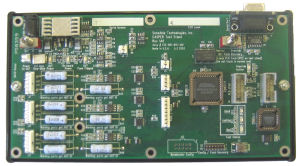

Bolton Engineering Inc constructed the Speed Sensor around an Analog Devices Dual Blackfin Processor, a mobile SDRAM, and serial Flash memory. The Fingerprint ID images were captured at 40MSPS over the Blackfin's Programmable Parallel Interfaces (PPIs). The Blackfin's internal timers were configured to provide synchronized timing signals for the Fingerprint Sensors. In addition to the Fingerprint Sensor interfaces, a miniature 20pin board-stacking connector was included to allow a future analog data acquisition board to be incorporated into the system. Bolton Engineering subsequently designed the acquisition board, plus a miniature power supply board.

Project Scope

Bolton Engineering wrote the specification, designed the schematics, obtained vendor quotes, designed the 8-layer circuit board, wrote diagnostic and driver software in 'C', debugged the system, and delivered over seventy working prototypes.

Palomar Medical Technologies was developing a handheld mass-market laser hair removal system and required a reliable way to control laser exposure time as the device moved over a user's skin. Various speed-sensing technologies were tested and rejected. The most promising technique used two capacitance-based fingerprint identification chips to take a rapid succession of images that were processed by a Digital Signal Processor (DSP) to detect speed of movement.

The system had to fit in a tight handpiece together with the Fingerprint ID Sensors and optics. The Fingerprint ID sensors were mounted on flexible circuit boards to ensure good signal integrity and minimize the packaged size. All handpiece electronics had to be squeezed on a single 1.2" x 1.6" board. The power supply subsystem was initially mounted separately, in a base station, but was later incorporated into the handpiece. The system had to take minimal power, as there was no airflow and no space for adding a fan. The correlation-based speed detection software required significant processing capability.