PROJECTS

PDF Thermal Imaging Camera

System Overview

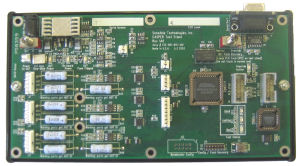

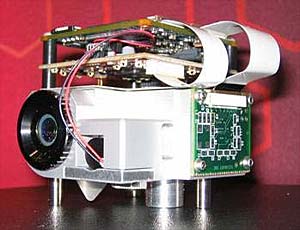

Redshift Systems had created a first-generation prototype using a commercially available Analog Devices Blackfin DSP evaluation board and a custom camera board. Although they had an engineer capable of doing the design, he was overloaded with other projects. Bolton Engineering took the key features from the prototype, made component selection trade-offs for availability and size, added required I/O, and created a highly integrated two-inch square module. In addition, Bolton Engineering designed a separate camera board, plus several small debug boards to aid in development. Bolton Engineering also created custom driver software that operated under the Analog Devices VisualDSP++ Kernel to capture and integrate successive camera frames, reformat the frames, and output them in NTSC format to a video display.

Project Scope

Bolton Engineering wrote the specification, designed the schematics, designed the 10-layer circuit board, designed wrote diagnostic and driver software in 'C' to operate under the VisualDSP++ Kernel, debugged the system, and delivered ten working prototypes.

Pictures © Redshift Systems, used with Permission.

Redshift Systems had developed a radical new technology that greatly reduced the cost of manufacturing Thermal Imaging Cameras (TICs). TICs are used in surveillance, and by emergency response personnel to identify people and doors in smoke filled buildings. Currently available products are expensive and are not widely deployed. Redshift's core technology, the Thermal Light Valve™ (TLV) translates thermal radiation into light that can be directly imaged by a standard CMOS camera chip. The TLV is based on an optical active thin film originally developed and commercialized by Aegis Semiconductor and current deployed in communication networks.