PROJECTS

PDF Black-I Landshark Ground Vehicle Robot

System Overview

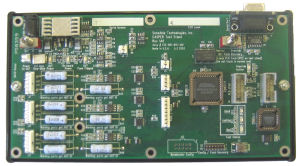

Black-I had developed an agile robotics platform based on COTS (Commercial Off The Shelf) computing hardware using a microcomputer and an Intel/Altera FPGA (Field Programmable Gate Array). The system required a custom board to control the motor servo amplifiers and to interface to the various on-board sensors. Bolton Engineering worked with Black-I to develop an expandable board containing a variety of expandable subsystems:

- Four Motor Quadrature Encoder interfaces (logic in FPGA)

- Eight-channel expandable A/D converter and D/A converter (logic in FPGA)

- Three-axis MEMS accelerometer and three-axis gyroscope

- Joystick interface

- High Power Motor Control interface

- Two expandable I/O slots into which boards with new functionality may be placed (logic in FPGA)

- Multi-Voltage Power Supply, for on-board logic and for external chassis-mounted electronics

For additional information, see www.blackirobotics.com. Click here for video.

Project Scope

Bolton Engineering wrote the specification, designed the schematics and circuit board, developed and simulated the Intel/Altera FPGA-based I/O system, fabricated and debugged the hardware, and implemented the on-board control software. Black-I was responsible for all system, navigation, communications and control software. The project was completed in eight weeks. The first-pass board was fully operational and required no changes.

Brian Hart started Black-I Robotics in 2006 after Brian's son, PFC John Daniel Hart, was killed in Iraq.

"Men shouldn't be asked to do a machine's job. With recent advances in robotics, unmanned ground vehicles are capable of taking on many of the dirty and dangerous jobs soldiers and first responders have traditionally risked their lives doing." - Brian Hart

Soldiers in Iraq were often required to enter difficult and dangerous situations without the proper tools, equipment and armor. Although using robots to assist soldiers was often discussed and promoted by the military, few systems had actually made it through to deployment. In response, Black-I developed a series of six-wheeled Unmanned Ground Vehicle (UGV Robots) that are strong, fast and affordable.