PROJECTS

PDF Lung Impedance Analyzer

System Overview

Bolton Engineering reviewed medical journals to understand what research had previously been performed and how the existing monitors functioned. The analog monitors had used a Fourier integration technique that required circuitry that was especially prone to component aging and temperature drift. Bolton Engineering determined that a microprocessor-based instrument could implement and expand upon these algorithms without being susceptible to the same drift errors.

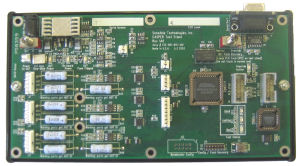

Bolton Engineering built an interface card that attached the monitor electronics to a PC, allowing all software to be written and debugged on the PC. Different algorithmic approaches were tested using bottles and elastic tubing to simulate the human lungs and trachea. "Flight recorder" data taken from a development team member attached to a ventilator were used to develop the filtering algorithms to discard poor data resulting from breathing irregularities. Measurement cycles were synchronized to the 60Hz power line to eliminate artifacts that might be introduced from power line noise. Thumbwheel switches set low and high alarm limits for all displayed parameters.

Bolton Engineering built the prototype electronics into a heart monitor enclosure to make it "psychologically" compatible with the operating room and to fit in existing equipment racks. Extensive shielding was included to allow the unit to function in the presence of EMI producing electrosurgical devices.

Results

- Displayed lung Resistance, Compliance, Minute Volume and Breath Volume.

- Approved for operating room use without modification.

- Operated without incident in the presence of high EMI-producing electrosurgical devices.

- Turned on an alarm when displayed values went outside of preset low and high limits.

- Flashed display and sounded alarm when parameter went outside of preset limits.

- Measured lung wall pressure and airflow into and out of lungs using precision differential pressure and airflow sensors.

- Wrote algorithms using floating point math to ensure large dynamic range.

- Minimized computational load on the microprocessor by using arithmetic coprocessor.

- Constructed prototype electronics in heart monitor case to make unit "psychologically" compatible with operating room personnel.

- Researched and developed product over a nine month period.

Project Scope

Bolton Engineering designed the schematics, prototyped and tested the circuitry, developed the software on a PC, built a stand-alone version for operating room trials, and worked with the hospital technical staff to ensure operating room approval.

An anesthesiologist had a concept for a digital instrument that would monitor lung operation during surgery by modelling the lungs as an RC (resistor, capacitor--also called "compliance") network. Researchers had previously built analog computers that could extract the network parameters but they had proved too unreliable and inflexible for operating room use. A microprocessor-based instrument would be significantly more reliable and would add considerable functionality.