PROJECTS

PDF Prototype Bicycle Power Meter

System Overview

The “Twanger” Bicycle Power Meter uses Digital Signal Processing (DSP) to compute power by passively monitoring a bicycle chain. Unlike competing power meters that require users to replace key bicycle components with custom ones containing strain gauges, the “Twanger” measures the power transmitted through the Bicycle drive chain by monitoring the chain resonant frequency and the chain speed.

Power is the product of force and speed. In a bicycle, transmitted power is the product of the tension of the upper chain run and the chain speed. Speed can be directly detected by monitoring the links as they pass a sensor. Chain tension can be derived from the frequency of vibration of the chain, which depends only on the tension, and the fixed parameters of mass and length.

Project Scope

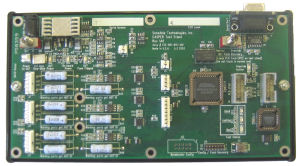

Bolton Engineering, Inc. worked with CC Kinetics to develop a prototype based on a Texas Instruments (TI) DSP that could be tested on an actual bicycle. A Bolton Engineering software engineer took the original development code and converted it to run on the chosen low-power Texas Instruments DSP. TI signal processing libraries were used to streamline the development process.

Bolton Engineering, Inc. also allowed CC Kinetics use of its office space to demonstrate the product to prospective investors and to prospective licensees. Subsequently, the “Twanger” technology was patented (US patent 6,199.021) and licensed to Polar, and is now available as the Polar “Power Tap.”

Note: Bolton Engineering did not play an active role in the final design of the final Polar Power Tap, which was designed from scratch by Polar Electro. See more information here.

Bolton Engineering, Inc. worked with CC Kinetics, Inc. to develop the first embedded prototype of a proprietary passive Bicycle Power Meter. Code named “The Twanger” during development, the Power Meter measures the power transmitted through the Bicycle drive chain by monitoring the chain resonant frequency and the chain speed.